Final Assembly, Testing, and Packaging

In the dynamic world of Electronic Manufacturing Service (EMS) our differentiating factor lies in our ability to add value to our customers.

We provide comprehensive Final Assembly, Testing, and Packaging (FATP) services, supporting a diverse range of products and industries. Our capabilities span from low volume-high mix to high volume production, enabling us to flexibly adapt to our customers' evolving demands.

Our FATP services cover a broad spectrum of sectors, including Smart Consumer Electronics, Cloud and Networking Products, Computing Devices, Automotive Electronics, Electronic Components, and more. We deliver tailored assembly solutions that integrate PCB mounting, subsystem integration, functional testing, and quality assurance—ensuring every product meets the highest performance and reliability standards.

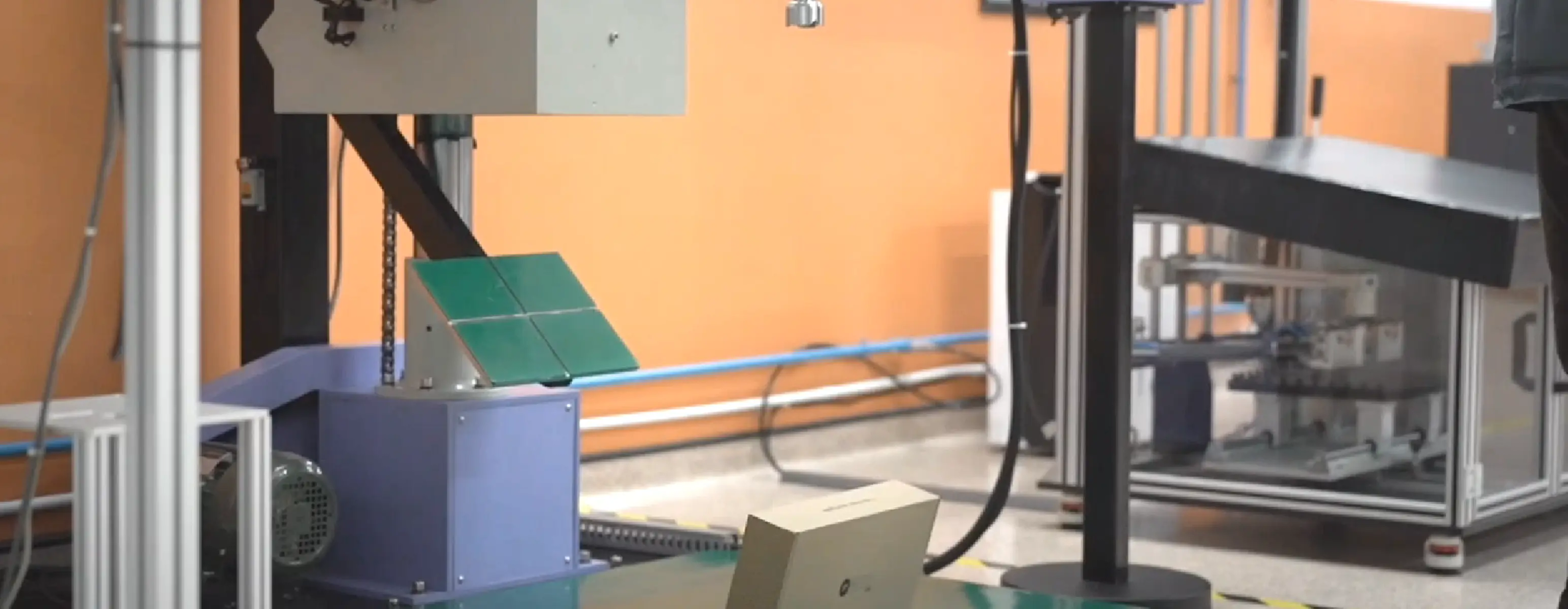

Testing, Inspection, and Packaging for Reliable Delivery

Our testing processes are tailored to each product type, ensuring functional integrity, reliability, and performance throughout testing, packaging, and final inspection before shipment. Our tests include:

Functional Test

Ensures that the device can be turned on and all key features are working.

Connectivity Test

Ensures that the device can connect properly to the network and other devices.

Performance Test

Tests the performance of the product such as processor speed and product durability.

Durability Test

Products are tested for durability under extreme conditions such as heat, humidity, and shock.

Visual Quality Test

The product is checked to ensure that the components are flawless and performance is optimized.

Final Inspection

Final inspection will be carried out before the product is sent to our customers.

Packaging

Products that pass the test will be cleaned and pacakged according to brand standards.

Ongoing Reliability Testing (ORT)

The final testing process carried out to ensure that a product is fully ready before being released to the public. This testing covers aspects of functionality, performance, security, and quality to ensure that the product can operate according to the expected specifications under real conditions. Through ORT, the company ensures that every product launched has passed a rigorous evaluation stage and is ready for use by end users.

- 1. Waterproof Test (up to IPX9)

- 2. Environment Test (Temp -80~ +220oC)

- 3. Salt Spray Test

- 4. Dust Test

- 5. Button Life Test

- 6. Vibration Test

- 7. Connector Strength Test

- 8. Pull & Plug Test

- 9. Abrasion Test

- 10. Back Pocket / Squeeze Test

- 11. Twist Test

- 12. Radio Frequency Test (2G-5G, BT, Wi-Fi)

- 13. Micro Drop Test

- 14. Manual Drop Test

- 15. Corner Drop Test

- 16. Free / Speed Drop Test

- 17. Ball Impact Test

- 18. ESD Simulator Test (1-16 kV)

- 19. Cross Cut Section

- 20. Pressure Test

- 21. Hinge Test

- 22. Tumble Test

Complete Final Assembly & Testing Solutions

From assembly to packaging, we ensure your products meet the highest quality standards before reaching your customers.