High-Accuracy Metal Stamping Solutions

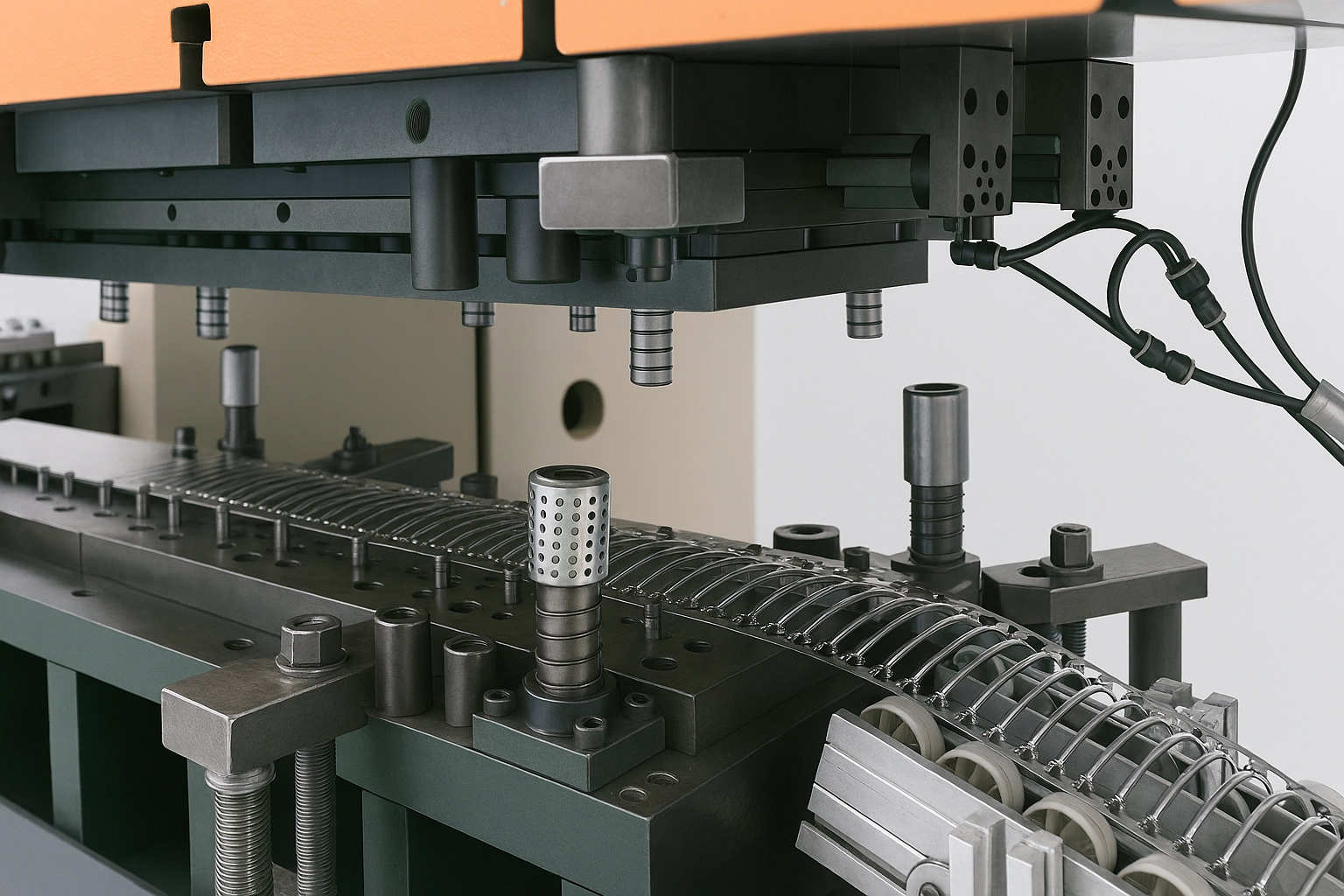

Our Metal Stamping Division specializes in the production of high-precision, durable components using progressive, compound, and deep-draw stamping processes. With in-house tooling capabilities, material versatility, and stringent quality control, we consistently deliver reliable performance for demanding sectors such as automotive, consumer electronics, home appliances, and industrial equipment.

Equipped with a comprehensive range of stamping and press machines, we process various materials including stainless steel, aluminum, and copper. Our services cover tool and die design, maintenance, and storage, along with surface finishing options such as secondary processing, spray painting, and plating—offering an all-in-one solution for ready-to-assemble metal components tailored to your specifications.

Our Services

Tooling Design, Fabrication & Maintenance

- DNE Laser Cutting Machine (1 KW & 3 KW)

- CNC Bending (80 & 135 Ton)

- CNC Turning

- CNC 4 Axis Milling

- CNC Wire Cut

- Super Drill Machine

Looking for Precision Metal Stamping Services?

Enhance your production with high-accuracy metal stamping tailored for industrial with powered by advanced tooling and quality control systems.